MEDICAL & HEALTHCARE TECHNOLOGY

At ZW Precision Hardware, we recognize the critical role that high-precision components play in the medical and healthcare technology sector. These components ensure the optimal performance of medical devices while prioritizing patient safety. By integrating advanced manufacturing techniques with innovative design, we deliver precision-engineered solutions widely utilized across various medical applications.

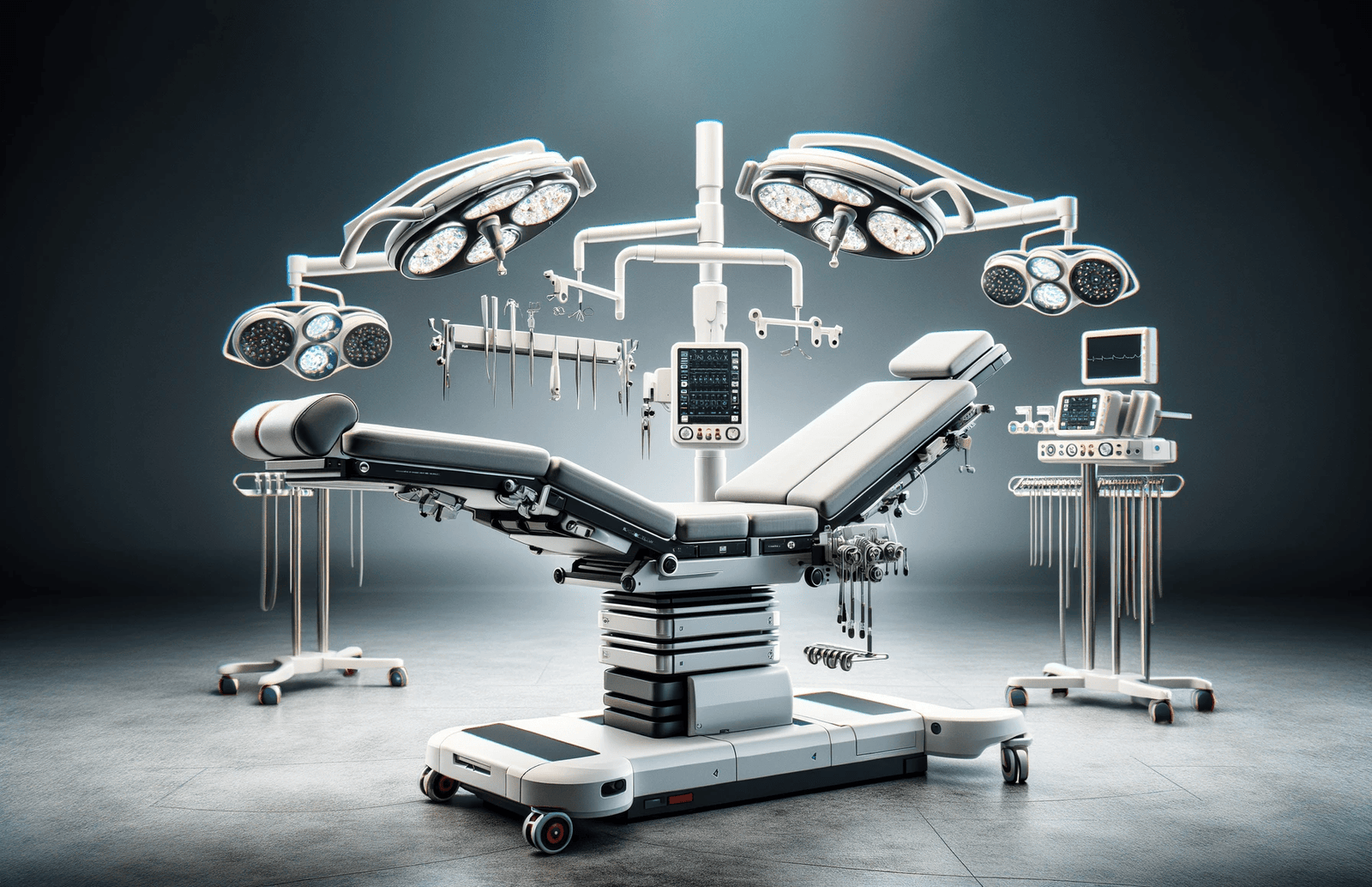

Essential Components in Medical Devices

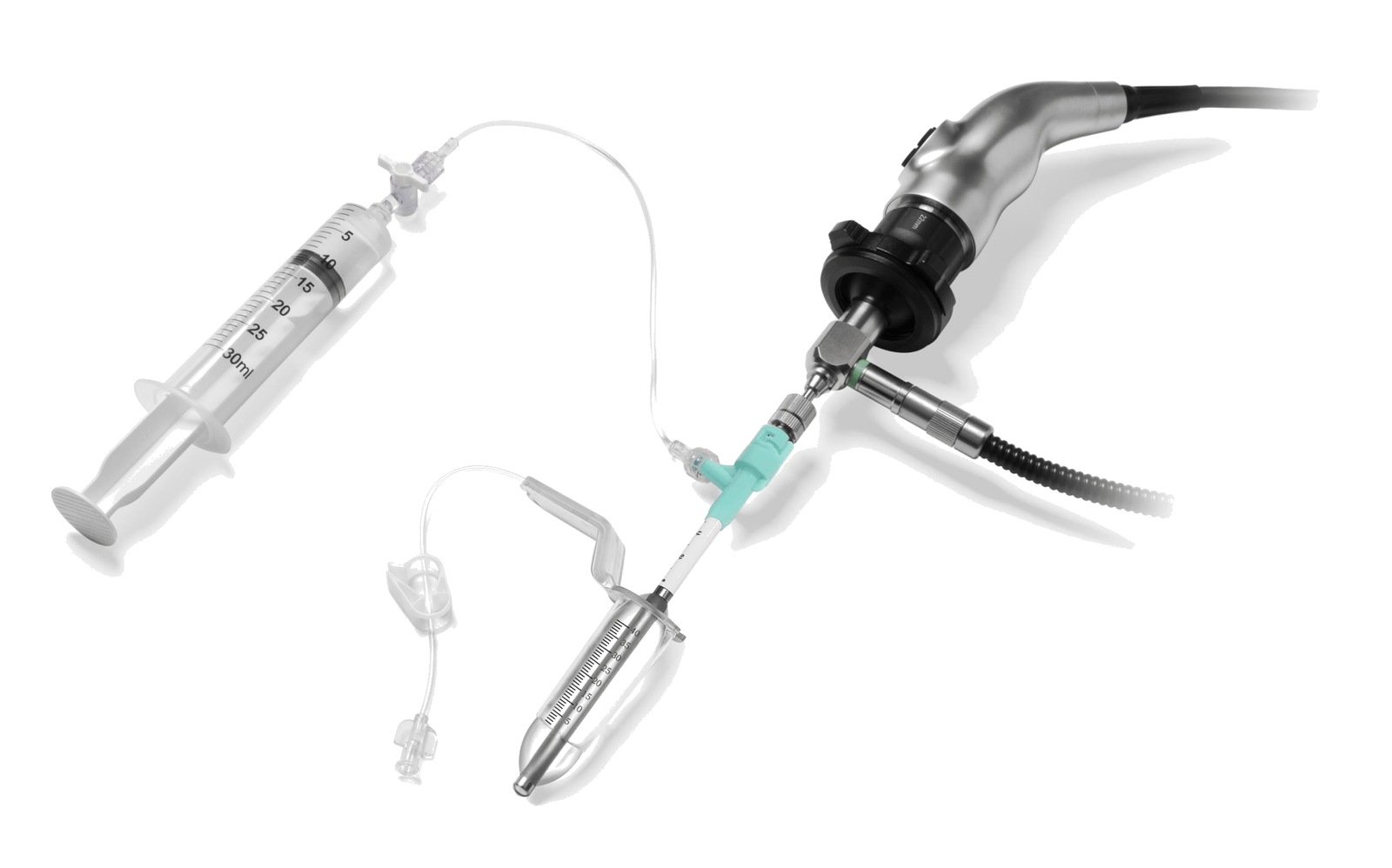

Spring assemblies, stampings, pressings and wire forms are fundamental to the functionality of medical devices. Precision springs provide stable mechanical performance and reliability in surgical instruments, syringes, infusion pumps and implantable devices. High-precision stampings are integral to MRI machines, X-ray equipment and other diagnostic devices, ensuring accuracy and long-term durability. Additionally, wire forms are used in prosthetics, orthopedic devices and rehabilitation equipment, enhancing both comfort and functional support for patients.

Solutions In The Healthcare Sector

Our manufacturing processes adhere to the stringent quality control and regulatory requirements of the medical industry. We ensure that all components meet the highest standards of cleanliness, biocompatibility and long-term stability, guaranteeing their suitability for medical applications. We offer tailored design solutions to meet the evolving demands of medical equipment manufacturers. Our customized approach allows us to develop flexible and precise solutions that enhance device performance, reliability and overall innovation in the healthcare sector. Through our high-precision manufacturing capabilities, we support the global advancement of medical and healthcare technology, enabling cutting-edge solutions that improve patient care, drive innovation and contribute to progress in the medical field.

.png)